A genetically engineered enzyme could provide a more elegant solution for plastic bottles made of polyethylene terephthalate (PET), which are nearly 70 percent of the market and can persist for hundreds of years.

While analyzing the crystal structure of PETase, a recently discovered enzyme that digests PET, researchers created a fortuitous accident - they engineered an enzyme that is much better at degrading the plastic than the natural kind, which was discovered in 2016 and is thought to have evolved in a waste recycling plant in Japan. It allows a bacterium to degrade plastic as a food source. It had to have evolved somewhere recently because PET was only patented as a plastic in the 1940s.

The goal was to determine its structure, but they ended up going a step further and accidentally engineered an enzyme which was even better at breaking down PET plastics.

Serendipity in basic research

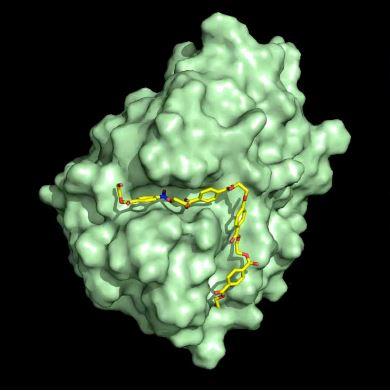

At the Diamond Light Source in the United Kingdom, a synchrotron that uses intense beams of X-rays 10 billion times brighter than the sun to act as a microscope powerful enough to see individual atoms, an ultra-high-resolution 3D model of the PETase enzyme was generated. Seeing the 3-D atomic structure of PETase revealed that is looks very similar to a cutinase, but it has some unusual features including a more open active site, able to accommodate man-made rather than natural polymers. The differences indicated that PETase may have evolved in a PET-containing environment to enable the enzyme to degrade PET.

That gave them the blueprints to engineer a faster and more efficient enzyme. They genetically modified the PETase active site to make it more like a cutinase and the unexpected happened; the researchers found that the PETase mutant was better than the natural PETase in degrading PET. What takes centuries in nature could not happen in days. They have found the enzyme can also degrade polyethylene furandicarboxylate, or PEF, a bio-based substitute for PET plastics that is being hailed as a replacement for glass beer bottles.

“I think this is very exciting work. Enzymes are non-toxic, biodegradable and can be produced in large amounts by microorganisms (bacteria and fungi)," said Dr. Oliver Jones, Reader of analytical chemistry at RMIT University in Melbourne. "Although most people don’t know it, enzymes already help us out in many areas of everyday life such biological laundry detergents and in the food, leather, and textiles industries."

Citation: Harry P. Austin, Mark D. Allen, Bryon S. Donohoe, Nicholas A. Rorrer, Fiona L. Kearns, Rodrigo L. Silveira, Benjamin C. Pollard, Graham Dominick, Ramona Duman, Kamel El Omari, Vitaliy Mykhaylyk, Armin Wagner, William E. Michener, Antonella Amore, Munir S. Skaf, Michael F. Crowley, Alan W. Thorne, Christopher W. Johnson, H. Lee Woodcock, John E. McGeehan and Gregg T. Beckham, Characterization and engineering of a plastic-degrading aromatic polyesterase, PNAS April 17, 2018. DOI:10.1073/pnas.1718804115