For those of us who cook, a cast-iron skillet is an early acquisition, they hold heat well and evenly, and best of all they are cheap. But food sticks to cast-iron unlike those more expensive non-stick, tri-metal $200 pans, so most cooks are told to “season” the pan, coating it with olive oil and baking it. Over time, it develops a non-sticky, if not non-stick surface. As it turns out, unbeknownst to the cooks in our life, seasoning a pot also reduces bacterial contamination. A group of researchers in Toronto reports how an industrial version of seasoning may help reduce bacterial contamination that causes food poisoning.

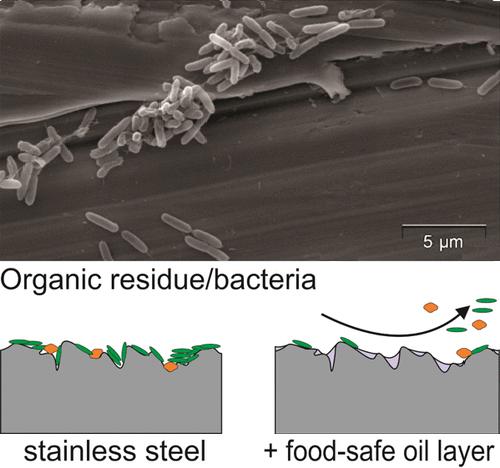

Stainless steel, rather than cast-iron, is commonly used for food processing. And this equipment is thoroughly cleaned and disinfected between batches of production. And while they appear bright and shiny to us, for bacteria stainless steel has a variety of grooves, scratches, and pits that serve as hiding places for organic residues that serve as bacterial meals. This rough microstructure not only provides a food source but serves as a hideaway for bacteria to attach to the steel and more importantly, secrete a combination of sugars, protein, fats, and DNA to form biofilms. Biofilms, in turn, encase and protect bacteria especially from soap and water and disinfectants. Bacteria protected by biofilms are a thousand times less susceptible to antimicrobial agents than those left unprotected. The bacteria we associate with food poisoning, Salmonella enterica, Listeria monocytogenes, E. coli, Bacillus cereus, Shigella sp and Vibrio sp all form biofilms.

The current strategy in preventing this type of contamination, biofouling would be the applicable jargon, is to clean and disinfect. But disinfection and cleaning are less effective on biofilms and their encased bacteria so preventing the initial attachment of bacteria may be a better approach.

Nature as is frequently the case, providing an inspirational model, the slippery non-wet surfaces of the Pitcher Plant – a carnivorous plant that traps its victims in a deep well with slippery sides. The pitcher plant secretes, a thin lubricating liquid on the leaf that does not mix with water. The first of the man-made products inspired by nature’s ingenuity is LiquiGlide the coating that allows a viscous liquid, ketchup, to flow effortlessly from the bottle (no hand thumping here) leaving no drips behind. The Toronto researchers develop a similar product, they are termed SLIPS [1], using food grade cooking oil. The coating reduces bacterial levels a thousand fold and filled in the little nooks and crannies that were home to the bacteria and their biofilms. And even though wear and tear depleted the surface of excess oil, residual oil trapped in the microcracks still prevented bacterial contamination. Simple washing was effective in removing all bacteria eliminating the disinfectants and with their elimination also perhaps reducing antimicrobial resistance.

The more viscous, thicker, the oil, the better the result. Olive oil seemed to work particularly well, just as it does when seasoning a cast iron skillet. Perhaps the inspiration for this technique would have been found a bit sooner if the scientists had spent more of their free time cooking with iron. Am I the only one that finds it ironic that once again, my mom was right?

[1] Slippery Liquid-Infused Porous Surfaces

Source: Food-safe modification of stainless steel food processing surfaces to reduce bacterial biofilms ACS Applied Materials and Interfaces DOI: 10.1021/acsami.8b03788