I was drawn to the article simply by its title, On Oreology, the fracture and flow of “milk’s favorite cookie.” Very clever to change rheology, the study of the flow of materials, into Oreology when discussing the flow of Oreo’s white stuffing. As the researchers write,

“While rheology cannot address questions like whether beans belong in chili, or whether a spoon or fork is the more appropriate utensil for mac ‘n’ cheese,” it can help us understand why the creamy filling is predominantly on one of those delicious cookie wafers when we twist the Oreo apart.

When the wafers are counter-rotated, creme torsionally deforms in shear, flows, and ultimately fractures, leading to separation of two cookie parts. … In our tests, adhesive failure is most common when manipulating cookies by hand or laboratory equipment….”

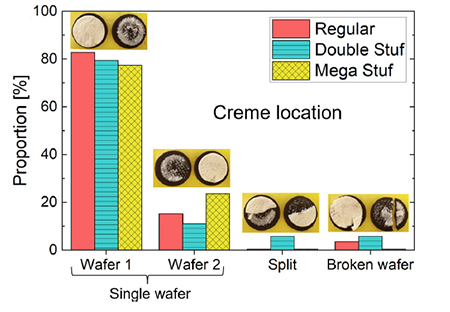

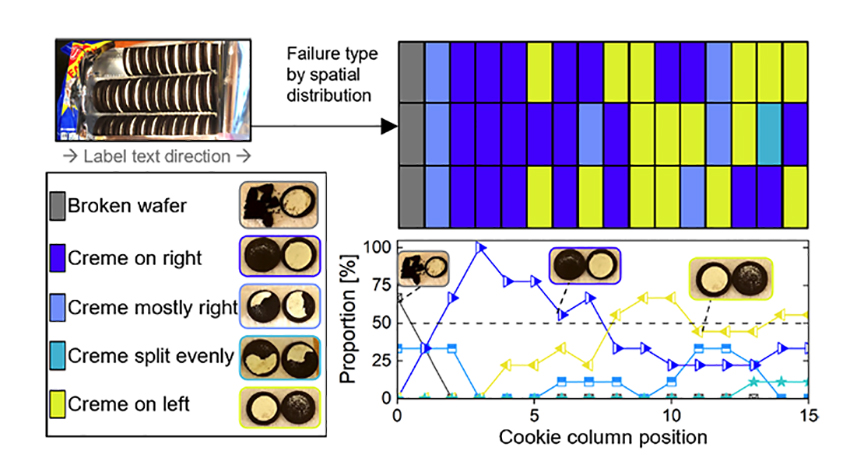

Adhesive failure refers to how the crème “delaminates” onto just one of the two wafers. Cohesive failure refers to a breakdown in the crème itself, leaving some on each wafer. Thorough scientists that they were, they further demonstrated that the amount of stuffing had little effect. Moreover, the wafer retaining the crème had the same orientation (on the left or right) throughout the package – a clue to why one side over another.

Adhesive failure refers to how the crème “delaminates” onto just one of the two wafers. Cohesive failure refers to a breakdown in the crème itself, leaving some on each wafer. Thorough scientists that they were, they further demonstrated that the amount of stuffing had little effect. Moreover, the wafer retaining the crème had the same orientation (on the left or right) throughout the package – a clue to why one side over another.

During the manufacturing process for the Oreo, the crème is placed on one wafer, and the second wafer is laid on top. The slight difference in the initial contact determines, for a large part, which wafers more firmly hold the crème and retains it when we twist the Oreo apart.

To make these determinations, the researchers affixed one side of the cookie to a plate. They used a “torsional laboratory rheometer” [1] to twist the other wafer at a constant speed, 3.7 rotations per minute. For the quantitative amongst us, the torque required to separate the wafer from its crème was 0.1 N⋅m – a Newton meter, a measure of the force applied at a distance. For us, outside the scientific community, it is 0.73 pound-feet. For comparison, it takes 2 N⋅m to twist the cap off a beer bottle. As the researchers note, NASA has determined we can apply 1-5 N⋅m using a thumb-forefinger grip – twisting apart an Oreo is easy.

The failure strain, the amount of force involving the breakdown of a material, in this case, the Oreo, is towards the brittle end of the spectrum, like a “crumbly Romano” cheese or foie gras; far greater, double that of peanut butter or crème cheese. While the amount of crème filling measured by its height had no discernable impact on wafer delamination, the filling spread across the wafer required more torque. The filling flavor had no effect.

“Cookie connoisseurs may be prone to slowly or rapidly twisting their sandwich cookies (perhaps based on hunger or anxiety levels).”

As you might anticipate, more rapid twisting did alter the measure of stress failure, but it did not change which wafer got the crème. Finally, they consider whether packaging and shelf time had a discernable impact, using “a single, freshly opened box of Family Size regular Oreos.”

The sharp-eyed amongst us will note two “trends.” First, again as might be anticipated, damaged wafers are found at the edge of the packing. Second, the wafer holding the crème after twisting is towards the inner portion of the package, away from the edges. This finding seems to fly against the original discovery of a consistent orientation.

“This may indicate that environmental impacts (ambient heat or mechanical perturbations) influence the cookies in individual boxes, having the greatest influence on cookies near the perimeter. As these influences are uncontrolled by individual consumers, this sensitivity may diminish the predictability of creme failure type and location between different boxes of cookies. … How much this distribution changes between different boxes, cookie types, and season or other environmental impacts, and why, may be a topic for future study.”

For the Dunkers amongst us

The introduction of milk into the delightful Oreo wafer increases its goodness and perhaps its mouthfeel, but it can dramatically reduce the mechanical strength of the wafer. 95% of its mechanical strength is lost after dunking a wafer into 1% milk for five seconds – it broke apart within 30 seconds. Maintaining cookie integrity, not separating wafer and crème, allowed the filling to maintain mechanical strength for an additional 30 seconds. The researcher note,

“Although this is beyond the scope of the current study, there is likely a “sweet spot” between immersion time to load the cookie with milk and consumption time before loss of integrity.”

Hopefully, we can expect further investigations from the research team.

[1] For those interested in pursuing their own investigations, the researchers provide at the end of the article a means of creating a similar rheometer at home – assuming your home has a 3D printer.

Source: On Oreology, the fracture and flow of “milk’s favorite cookie” Physics of Fluids DOI: 1063/5.0085362